Non-Evasive Test

Instruments

One of the most underutilized non- evasive test instruments in

the HVAC fields is thermal imaging. I

first utilized the technology for inspection of motor control and load centers

about 15 years ago. The services were provided by an electrical contractor

business partner and incorporated into our electrical preventive maintenance

program for annual inspections.

Value of Thermal

Scanning as a Reactive Maintenance Tool

After a myriad of roof leaks in an 11 year old building, and

my concerns that the root causes were not properly being identified and

corrective actions taken, I employed this technology. The roof leaks and

damaged insulation areas, as a result of the leak, were identified within twenty

minutes. It eliminated the destructive testing method of taking core samples of

the roof material, insulation and patching along with the “wait and see”

approach. More importantly, it saved countless in-house roofer labor hours and

callbacks for the same leak until the issue was finally resolved.

Thermal Scanning to

Identify Heating Loop Issues

Seeing the results, success and benefits of the thermal

imaging as a preventive maintenance as well as a diagnostic tool I purchased

a lower to mid-level price point model at the time as well as training. While more features continue to be added, the

biggest advancement to occur, in my opinion, in thermal imaging is the reduction

of cost. I became responsible for a

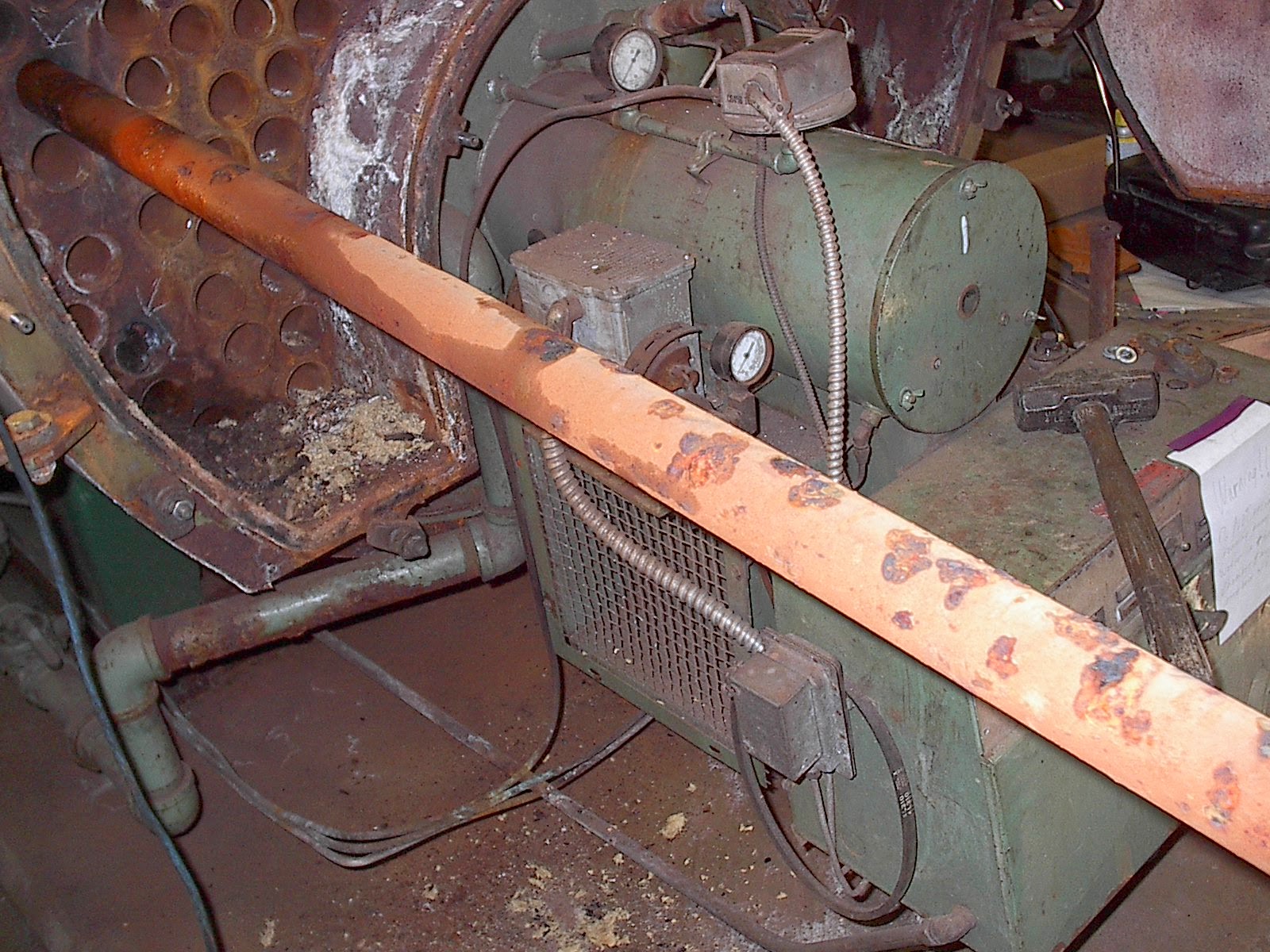

healthcare facility that had an aged infra-structure. The facility

employed two screw chillers and three hot water boilers in a dual temperature

configuration with two zones for three buildings.

Energy usage was substantially higher than similar size

facilities, along with the inability to maintain proper water treatment of the

closed loops. Valve identification charts along with all Mechanical,

Electrical, and Plumbing (MEP) drawings were non-existent upon my assuming

responsibility, not to mention more than half the valve tags were missing as

well. I love a challenge, and this was

clearly a challenge. Hand sketches were made of the piping and panoramic pictures

taken of the central plant and pieced together then mounted on foam board for

offsite reviewing; valves were numbered and valve charts developed. After

existing water flow pattern and valve positions were documented, thermal scans were first used to

identify valves that were passing. In addition, valves were found in the

incorrect positions with respect to the season. Corrective actions were taken

and correct water flow patterns were established for the seasonal operational

mode.

An area of concern was the inability to maintain proper

water treatment on the closed loops. I

suspected a leak or open drain valve, but none was evident in the mechanical

rooms. Water meters were installed on

the boiler and chilled water makeup lines. The boiler make up on Zone A

indicated almost 950 gallons per day were being added to the system. I had

staff check every accessible area of piping as well as all air vents and fan coil

units. No leaks were found other than minor valve packing leaks. One area of

the piping distribution system was under slab. When a thermal scan was

performed on the area, a leak under the slab was identified. The heat signature

continued in the direction of an outside courtyard to a point about 30 yards

away. At this location there was a set of store front doors; one side was

inoperable due to a settling of a canopy support column. Thermal scan of this

area indicated a temperature 78 degrees when the outside temperature was 33 degrees.

The thermal scans not only located a leak, but the root cause of the column

settling. A 21 – 26% reduction in energy associated with the equipment was

realized depending on the month and ambient conditions as a result of the

corrective actions. What could not be quantified was the resulting thermal

satisfaction in terms of temperature and humidity control in the building. Unfortunate

consequences of the condition were boiler tube failures from the lack of water

treatment and oxygen.Proactive Maintenance

The use of thermal scans ranging from bearing, motors, air duct

leakage to identifying blocked passages of chilled water coils, thermal scans

are another method to determine a cause, or contributing factor of a

thermal complaint or problem. Thermal

scans are an efficient use of time and labor resources. The use of thermal

scans allows an organization to move from a reactive to a preventive mode to

improve operational efficiencies.